1976

1976Dipl. Ing. A. Kutschelis & Sohn

Technische Lehrmittel Construktion

D- 59425 Unna

Germany

web: http://www.telc.de

mail: mail@telc.de

phone.: +49 (0) 2303 239999

facs: +49 (0) 2303 239990

| First internal combustion engine to be operated as 4-stroke and 2-stroke | |||||||

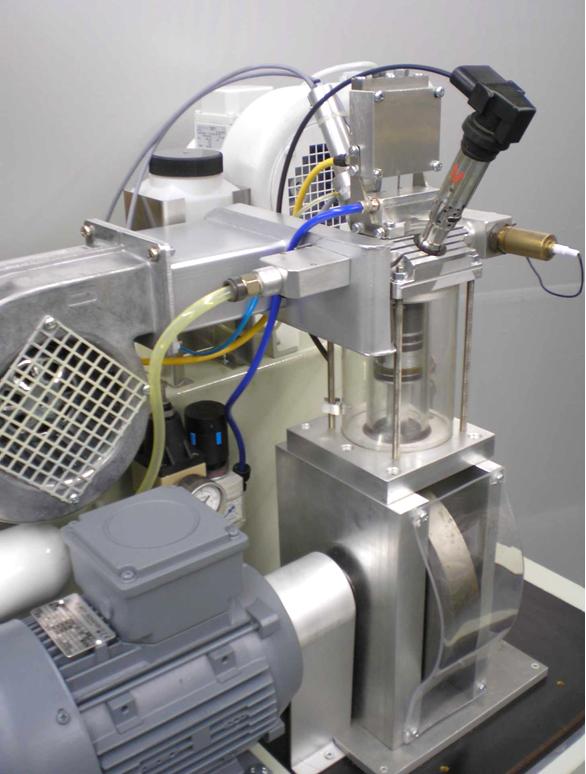

| The small engine for laboratory practice, which is already famous for its fully variable valves actuation , was redesigned so that it can be operated either in 4-stroke or in 2-stroke mode. This is possible, because all its functions are controlled completely electronically. The new direct injection, which was realized with the reinforced piezopump, allows injection into compression stroke after ending of the flushing phase. Flushing is made by the correct setting of the valves open phase around LDC and with flushing air which is taken from the pressed air supply, always used with the engine. Control and data acquisition is done from PC screen same like before. Also loading and saving of data sets of performance conditions like coldstart, fulload800, partialload800 etc. are done same way as before during running. So can be switched completely freely also between 2-stroke and 4-stroke data sets. Flushing air supply however should be disconnected in 4-stroke mode. Otherwise the engine would be overcharged.

Regarding this the new design provides not only the 2-stroke operation but also the overcharging of the engine. | ||||||

| |||||||

Screen with: | |||||||

|

| ||||||

Stichworte: Motortechnik Übungsstand, Leistungsprüfstand, Motorleistungsprüfstand, Ventilverstellung, Indizieren, Viertakt Motor Modell, Ottomotor Modell, Motorprüfstand Messtechnik, Motorprüfstand Datenerfassung, Verbrennungsprozess, Ventilsteuerung, Druckindizierung, Motorprüfstand, Glaszylinder-Motortechnik-Stand, Megatech, Glaszylinder, variable Ventilsteuerung, 4-Takt-Ottomotor, 4 Takt Motor, 4 Takt Otto Motor, gläserner Zylinder, transparenter Zylinder, Kurbeltrieb, Kolben, Ventile, Zündung, Verbrennung, verschiedene Kraftstoffe, Saugrohr-Einspritzung, Einspritzung, Einspritzmenge, Einspritzzeitpunkt, Einlass, Auslass, Ventilhub, Zeit-Öffnungs-Querschnitt, elektronische Zündung, Kennfeldzündung, Schließwinkel, geregelter Katalysator, Kurbelwellenstellung, Lambda-Sonde, Abgastemperatur, Drehmoment, Motorbetriebszustand, Zünden, Einspritzen, Kraftstoffmenge, Ventilsteuerzeiten, Frühzündung, Spätzündung, Überschneidung, Einlassventil, Auslassventil, Einlaßventil, Auslaßventil, Kennpunkt, Kennfeld, Indizieren, Zylinderinnendruck, Motordrehmoment, angesaugte Luftmenge, Expandieren, Auswerfen, Ansaugen, Verdichten, Warmlauf, Kaltstart, Indikatordiagramm, Vorzündung, gute Gemischbildung, Steuerverfahren, Laststeuerverfahren, Spätes Einlass Öffnen, Spätes Einlaß Öffnen, Spätes Einlass Schliessen, Spätes Einlass Schließen, Wandkondensation, Kraftstoffverbrauch, Kurbelwellenwinkel, Laufgrenze, fett, mager, stöchiometrisches Verhältnis, P/V-Diagramm, Drosselklappe, Gaswechselschleife, Vollast, Teillast, Volllast, Teilllast, Verlustminimierung, Vier-Takt-Motorbremse, Motorbremse, völlig variable Ventilsteuerung, variable Steuerzeiten, Lambda-1-Technik, Magerbetrieb, Leistungssteuerung, Valvetronic |

|||||||

| See also : Transparent engine | |||||||

| ©TeLC Unna 2004 | |||||||