| printable version | Miniplant PIRCA | |

| Philosophy of TeLC Miniplants:

TeLC Miniplants follow a standardized design principle which adopts to some extent the real situation in an industrial plant.So is found the field department and the control department. Field and control are both equipped with original industrial instruments. The control department contains the mimetic display and the control instruments. Deviating from reality the field which is concentrated in the mimetic display is to be physically connected with the control instruments may be with pneumatic hoses or electric wiring. So the trainee has got an additional task to solve. This connecting is eased in that way that | |

| especially for the wiring needs be taken no care with normal bipolar wiring and polarity. Connecting of pneumatics and electrics feels equal. The standardisation of the TeLC Miniplants goes so far as the dimensions hight 1.95m and depth 0.65m are equal. Only width differs between 2.2 and 2.9 m and of course weight. Within the abbreviation naming of the units is indicated the control task and instrumentation so e.g. here PIRCA means: Press - Indication - Registration - Control - Alarm | ||

Wide range of Training Tasks:

|

||

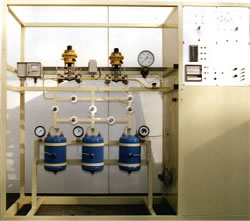

Buildup of PIRCA: A digital electronic controller is to be connected to the pressure control loop. 2 lines can be activated for the control. The pneumatic control valves have different capacity. For interfacing are used the p/I-transmitter and I/p-converter. A system of needle valves with positionscales together with the 3 reservoirs allow the simulation of delays up to third capacity. For data logging an electric 3-pen recorder with variable paper speed is existing. The alarm device can be connected to the alarm actuator in the field. |

||

Dimensions:

|

||

| ©TeLC Unna 2004 | ||